Sumec generators, equipped with either recoil or electric starting systems, utilize petrol as their fuel, making efficient management crucial for their operation.

The inclusion of features such as a Buying Guide, Anti-Fake System, and After-Sale Services underscores Sumec’s commitment to customer support and the importance of safe generator use.

To effectively manage fuel in your Sumec generator, understanding its fuel system and the nuances of fuel tank capacities, as highlighted in models like the SPG3000 with a 15L tank, is fundamental.

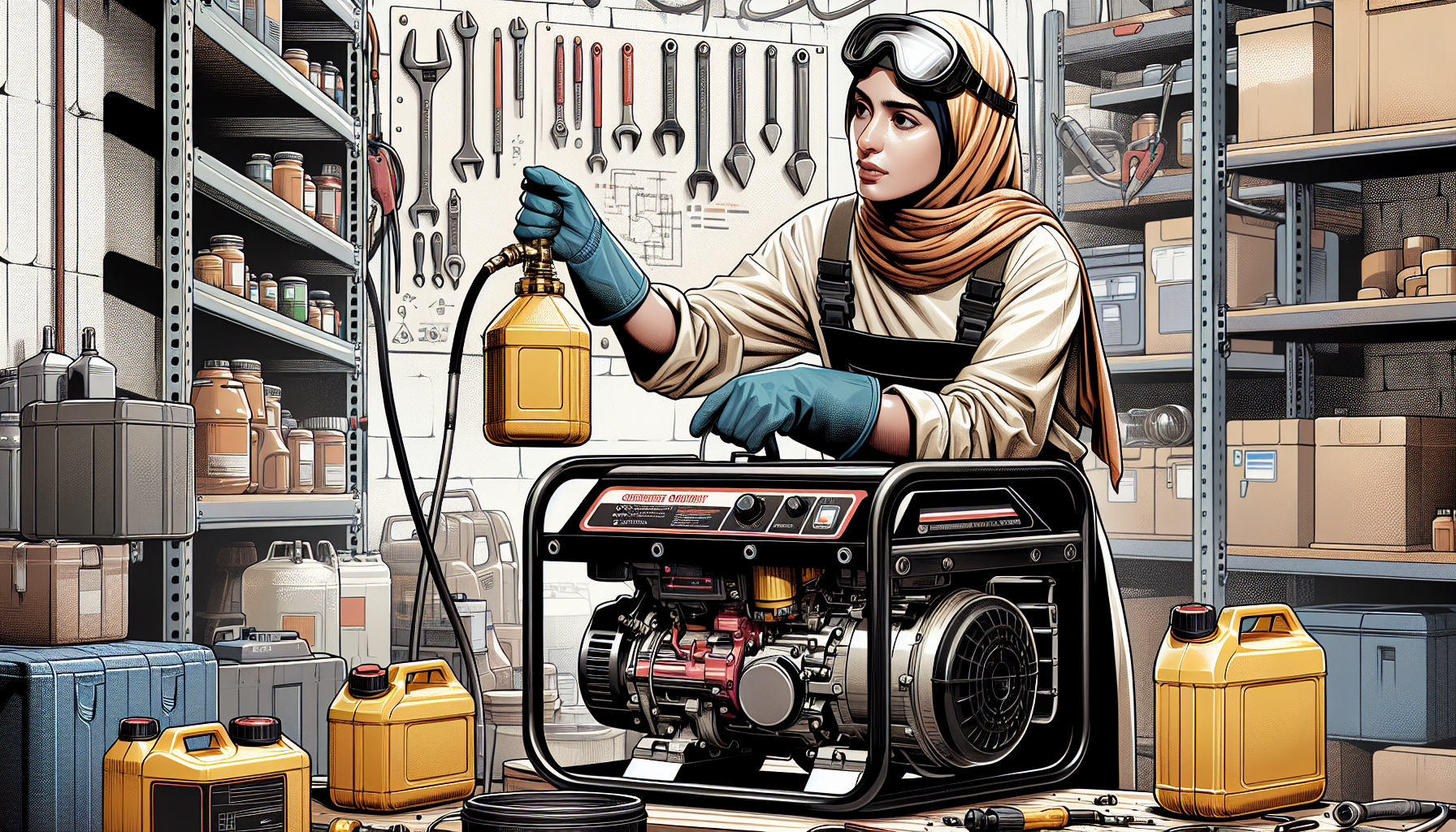

I have focused this guide on taking you through routine maintenance, adjustments, and the use of fuel additives to enhance fuel management.

Understanding Your Sumec Generator Fuel System

Let us move on with the journey to comprehend the heart of your Sumec Generator – its fuel system. This intricate network, often overlooked, is the lifeblood of your generator’s operation.

It’s a symphony of components working harmoniously, from the fuel tank storing potential energy to the carburetor mixing fuel and air, igniting life into your generator.

Understanding this system is akin to unlocking a new level of generator mastery, ensuring optimal performance and longevity.

Key Components of the Fuel System

- Fuel Tank and Lines: Sumec generators include a fuel system consisting of a fuel tank and fuel lines which are essential for transporting fuel to the engine.

- Fuel Pump and Filter: The fuel pump is tasked with delivering fuel from the tank to the engine, while the fuel filter, which should be replaced regularly, helps ensure clean fuel flow and prevents engine damage.

- Carburetor: Acting as a critical component, the flow of fuel into the engine is regulated by the carburetor. It collects, distributes, and regulates the fuel supply to maintain efficient operation.

Adjusting Your Generator for Fuel Efficiency

- Governor and Throttle Control: The governor arm needs proper alignment with the fuel pump pin to control engine speed effectively. This setup helps in managing the fuel efficiency by adjusting the amount of fuel pumped.

- Carburetor Adjustments: To reduce fuel consumption, tighten the carburetor screw to restrict fuel flow. After tightening, it should be loosened slightly to ensure the correct amount of fuel is allowed to pass, optimizing fuel usage.

Maintenance Tips for Optimal Performance

- Regular Checks: Inspect the spark plug for signs of wetness, indicating excessive fuel use, and monitor for thick, blue smoke which suggests a need for part replacements.

- Annual Maintenance: Change the fuel filter, clean vents, test piping and connections, and assess fuel quality annually to maintain the generator in peak condition.

Routine Maintenance for Fuel Efficiency

It’s very important to perform routine maintenance on your Sumec generator as this is very important if you really want to reduce fuel consumption.

Regular Maintenance Checks

- Fuel and Oil Levels: Always start by checking your fuel and oil levels. Regular top-ups and changes are crucial to maintain efficiency and ensure longevity of your generator.

- Cleaning and Inspections: Weekly cleaning of the generator’s exterior and monthly inspections of the fuel system are essential. Examine thoroughly for any indications of leaks, corrosion, or impairment.

- Battery and Electrical Systems: Test the battery and inspect all electrical connections to prevent failures during operation. Ensure that the battery is charged and the connections are tight and free from corrosion.

Seasonal Adjustments and Professional Servicing

- Seasonal Preparations: Adjust your maintenance routine according to the season. This includes using the right oil viscosity for winter or summer and ensuring the cooling system is adequate for the expected temperatures.

- Professional Inspections: Schedule at least an annual inspection by certified technicians who can handle complex tasks like load bank testing, and thorough checks of the air intake and exhaust systems.

Preventive Measures and Usage Tips

- Load Management: Operate your generator within its optimal load range to avoid issues like wet stacking and to maximize fuel efficiency.

- Alternative Power Sources: Consider integrating solar panels or wind turbines to reduce reliance on your generator, thereby saving fuel and reducing wear.

- Regular Exercise: Run your generator for at least 30 minutes monthly, loaded to at least one-third of its capacity to keep all mechanical parts lubricated and functioning properly.

Adjusting Settings for Improved Fuel Management

Here is the most important part, you need adjust the settings carefully in order to minimize the consumption of the fuel.

Minimizing Generator Usage

- Alternative Power Sources: To manage fuel efficiently, consider utilizing alternative power sources like solar energy or inverted generators. Implementing this strategy leads to a decrease in the utilization of fuel and also extends the lifespan of your Sumec generator by minimizing wear and tear.

- Load Management: Ensure that you neither over nor underload your generator. Operating within the recommended load limits is crucial for maintaining optimal fuel efficiency and preventing unnecessary fuel consumption.

Optimal Operation Practices

- Coolant Temperature Maintenance: Keeping the coolant temperature at the correct level is essential. Proper temperature control helps prevent incomplete combustion, a common issue that can lead to increased fuel usage.

- Appliance Management: Only run necessary appliances and adhere to timely servicing of your generator. Avoid running the generator on less than 50% load to optimize fuel consumption and reduce wastage.

Using Fuel Additives and Treatment

Using the fuel additives is very important if you want to achieve a better fuel reduction in your sumec generatot, it doesnt only save you some money but also time.

Regular Fuel Services and Additives

- Fuel Polishing and Treatment: Regular fuel services including fuel polishing are essential to maintain the quality of fuel in your Sumec generator. Fuel polishing involves sampling, testing, sterilizing, and filtering to remove particulates, bacteria, fungi, rust, and algae. Adding Sumec fuel treatment with every refill enhances power, saves fuel, and reduces the frequency of technical repairs.

- Benefits of Fuel Additives: Using fuel additives like Sumec fuel treatment offers multiple benefits. It extends the fuel’s usability, fights rust and corrosion in the fuel tank and engine, reduces friction and wear, improves performance, and helps in fixing hard starts. Regular use of such additives ensures that the fuel system remains in optimal condition, extending the life of your generator.

- Application of Fuel Treatment: To effectively use Sumec fuel treatment, pour it into a nearly empty tank before refilling. Mix one bottle of Sumec fuel treatment for every 25 liters of fuel. This practice helps in maintaining a clean and efficient engine, and it is advised not to refuel the tank until it is nearly empty to maximize the treatment’s effectiveness.

Conclusion

Throughout this article, we’ve explored a comprehensive guide to managing fuel in Sumec generators effectively, covering every aspect from understanding the fuel system to routine maintenance checks and the benefits of using fuel additives. Armed with this knowledge, you can ensure optimal generator performance and fuel efficiency, extending the lifespan of your equipment while minimizing operational costs.

Empowering your Sumec generator with efficient fuel management not only contributes to the sustainability of your power supply but also upholds the integrity of your equipment. As we conclude, remember that regular maintenance, strategic operation adjustments, and the utilization of fuel additives are key to maximizing fuel efficiency. This proactive approach to generator care promises reliability and performance, securing an uninterrupted power supply that supports your daily needs and activities.

FAQs

1. What steps can I take to enhance my generator’s fuel efficiency?

To improve your generator’s fuel efficiency, ensure regular maintenance and avoid both overloading and underloading it. Regularly remove carbon deposits, operate the generator at the right temperature, and choose the appropriate generator size and type for your needs.

2. How can fuel consumption be effectively managed in a generator?

Managing fuel consumption in a generator involves several key practices:

- Ensure timely servicing of the generator, similar to maintaining a car.

- Operate the generator at no less than 50% load capacity.

- Promptly remove carbon deposits.

- Use genuine replacement parts for maintenance.

- Consider using alternative power sources when possible.

- Select a high-quality generator set.

- Avoid overloading your generator to prevent excessive fuel use.

3. How do you adjust a generator’s carburetor to decrease fuel consumption?

Adjusting the carburetor to reduce fuel consumption typically involves fine-tuning the air-fuel mixture to ensure it is not too rich, which can waste fuel, or too lean, which may cause engine damage. It is advisable to consult the generator’s manual or a professional for specific adjustment procedures.

4. What are the best practices for maintaining gasoline in a generator?

To maintain gasoline in a generator effectively:

- Regularly start the generator and let it run for a few minutes to ensure it’s operational.

- Add stabilizer to the gas tank to preserve fuel quality.

- Replace stale gasoline and consider using it in your car to avoid waste.

- Change the oil periodically, regardless of usage.

- The spark plug should be inspected and, if deemed necessary, replace it.

- Check and maintain the air filter by cleaning or replacing it as needed.