Maintaining your Sumec generator is crucial for ensuring its longevity and optimal performance. Regular attention, particularly to the carburettor, can prevent common operational issues. The carburettor is a vital component in your generator that mixes air and fuel for internal combustion. Over time, it can become clogged with debris and residue, significantly hindering your generator’s efficiency.

When a carburettor clogs, it restricts fuel flow, leading to various issues, such as hard starting, stalling, and uneven running. To address this without removing the carburettor, you can use a carburettor cleaner specifically designed for this purpose. The basic steps to uncloge your Sumec Generator carburattor is very easy.

Ensure safety first, beginning maintenance, ensure the generator is off and cooled down. To avoid accidental starting, it is recommended to disconnect the spark plug wire.

Access the carburetor, by locating the carburettor’s air filter and remove it. This will give you direct access to the carburettor’s throat without eradicating it.

Apply carburetor cleaner by spraying a quality carburettor cleaner directly into the carburettor’s throat and onto the float and needle valves. These areas are prone to clogging and need thorough cleaning.

Let it Sit by allowing the cleaner to dissolve the gunk for several minutes. If the buildup is heavy, a second application might be necessary.

Clean external components while waiting, clean the air filter and inspect it for damage. A clean and intact air filter ensures no additional debris enters the carburettor.

Then you need to test what you have done once the carburettor is clean, reconnect the air filter and the wire of the spark plug. Start the generator to check if the operation has smoothed out. It’s crucial to observe any changes in performance, as this can indicate whether further cleaning or adjustments are needed.

By adhering to these instructions i will give you in this guide, you can proficiently unclog your generator’s carburettor without the complexity of removing it, saving time and possibly reducing maintenance costs.

Not only does regular cleaning of your carburattor improve the performance of your generator, but it also prolongs its lifespan, ensuring it remains a reliable power source when you need it most. This while down this guide, i will sure you a more elaborate way to unclog your sumec generator without removing it.

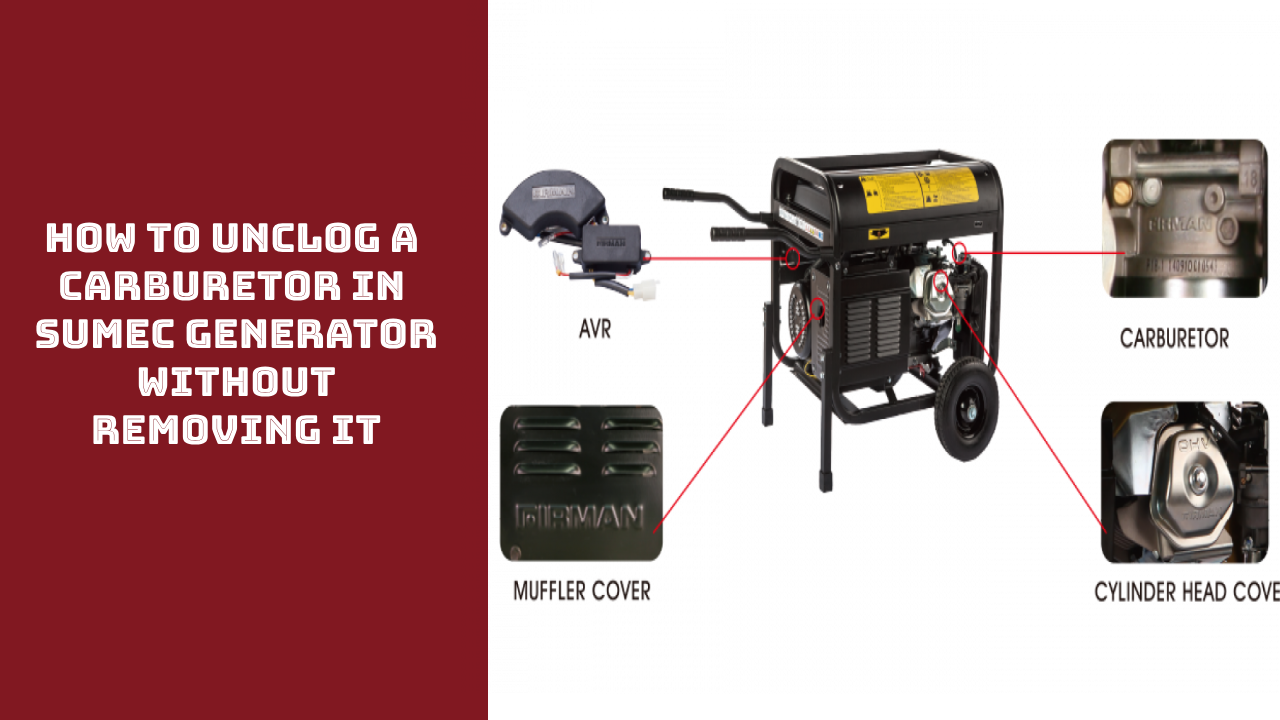

Understanding the Carburetor

Before diving into the unclogging process, let’s understand what a carburettor is and how it works. The carburettor is an essential component responsible for blending the fuel and air mixture in an internal combustion engine.

It operates on the Venturi effect principle, where a reduction in fluid pressure results from its forced flow through a constricted section of a pipe.

Carburetor Anatomy

The carburettor consists of several parts:

- The Throttle Valve controls the amount of air-fuel mixture entering the engine.

- The Venturi is the narrowest part of the carburettor, where the airspeed increases, reducing its pressure and allowing fuel to be drawn into the air stream.

- Jets are small openings where the fuel gets mixed with air before entering the engine.

- Float Chamber: This maintains the fuel level for the operation of the other components.

- Choke: This restricts the amount of air entering the carburettor, making the fuel mixture richer and aiding in cold starting.

Identifying a Clogged Carburetor

A clogged carburettor can cause problems, such as the generator not starting, running rough, or stalling during operation. If the generator has been sitting unused for a long time, the chances of the carburettor getting clogged are high.

The Process Of Unclogging Sumec Generator Carburetor

You’ll need a carburettor cleaner and a basic tool kit to unclog a carburettor. Below will provide you with a detailed process of cleaning your carburettor.

Step 1: Accessing the Carburetor

Accessing the carburettor usually involves removing the air filter. After removing the air filter, locate the carburettor and inspect it for dirt or damage.

Step 2: Cleaning the Carburetor

You can clean the carburettor without removing it using a carburettor cleaner. Spray the cleaner into the carburettor’s air intake and let it sit for a few minutes. This will dissolve any deposits blocking the carburettor’s parts.

Step 3: Reassembling

After cleaning, reassemble the carburettor, ensuring all parts are correctly reinstalled.

Step 4: Testing Your Work

Finally, start the generator and check for proper operation. If it runs smoothly, congratulations, you’ve successfully unclogged the carburettor!

Maintenance and Prevention

In generator maintenance, focusing on the carburettor ensures long-term, reliable performance. Regular maintenance of the carburettor not only prevents it from becoming clogged but also ensures that the engine runs smoothly and efficiently.

The carburettor is responsible for mixing air and fuel in the correct proportions to enable combustion in the engine. A clogged carburettor can lead to poor engine performance, increased fuel consumption, and engine failure.

To avoid these issues, it is essential to use fresh fuel. Over time, fuel can deteriorate as a result of oxidation and evaporation, leading to varnish and gum deposits within the carburettor. These deposits can obstruct fuel and airflow, hindering the generator’s performance.

Incorporating a fuel stabilizer is a wise practice if the generator is not in use for extended periods. Fuel stabilizers are additives that help preserve the quality of the fuel and prevent the formation of harmful deposits.

They work by stabilizing the fuel and preventing the chemical reactions that lead to degradation. This is particularly important for infrequent generators, as stale fuel is a common cause of carburettor clogging.

Additionally, regular cleaning of the carburettor is advisable. This involves removing the carburettor from the engine and using a carburettor cleaner to dissolve any build-ups of dirt and residue. This should be done annually or according to the manufacturer’s guidelines.

By adhering to these practices—using fresh fuel, adding a stabilizer when necessary, and performing regular cleanings—generator owners can significantly reduce the risk of carburettor problems and extend the lifespan of their equipment.

This proactive approach to maintenance ensures that the generator is ready to perform when needed, providing reliable power under various circumstances.

Conclusion

Unclogging a carburettor in a generator without removing it is a simple process that can save you time and money. The smooth functioning of your generator is possible with the right tools and patience. Always prioritize safety and consult your generator’s manual for specific instructions and safety precautions.